When planning the implementation of your first or next digital press, the PC specification you choose to run your software workflow will play an important part in the data rates you will be able to achieve. Assuming you are not bottlenecked by disk drive performance due to requiring intermediate disk accesses, you can generally expect data rates to rise with the computational power of your PC.

It might therefore make sense to review the PassMark scores for a range of CPUs within your budget and make your choice based on that, but this alone won’t be enough to tell you whether you’ll be able to drive your printer at full rated speed. Similarly, you may already have an existing PC system in mind but need to know if it will be powerful enough for your new requirements.

Ideally, you could set up an evaluation system to run some typical print jobs to get a definitive answer, but this could be costly and labor-intensive, especially if this is your first digital press.

It’s for this reason we created Direct Benchmark™: an analysis tool that exercises Harlequin Direct™, our ultra-high data rate RIPping and screening solution, with your choice of press configuration and print jobs, stepping through a tuning cycle to obtain a series of data rates and line speeds that can be achieved.

There are two main ways Direct Benchmark can help you: firstly, if you have an existing PC system to run on, you can install Direct Benchmark and gather your own results; secondly, you could base your decision on a database of Direct Benchmark results we are gathering here at Global Graphics Software from running a variety of jobs on a range of PC specifications.

Running Direct Benchmark yourself

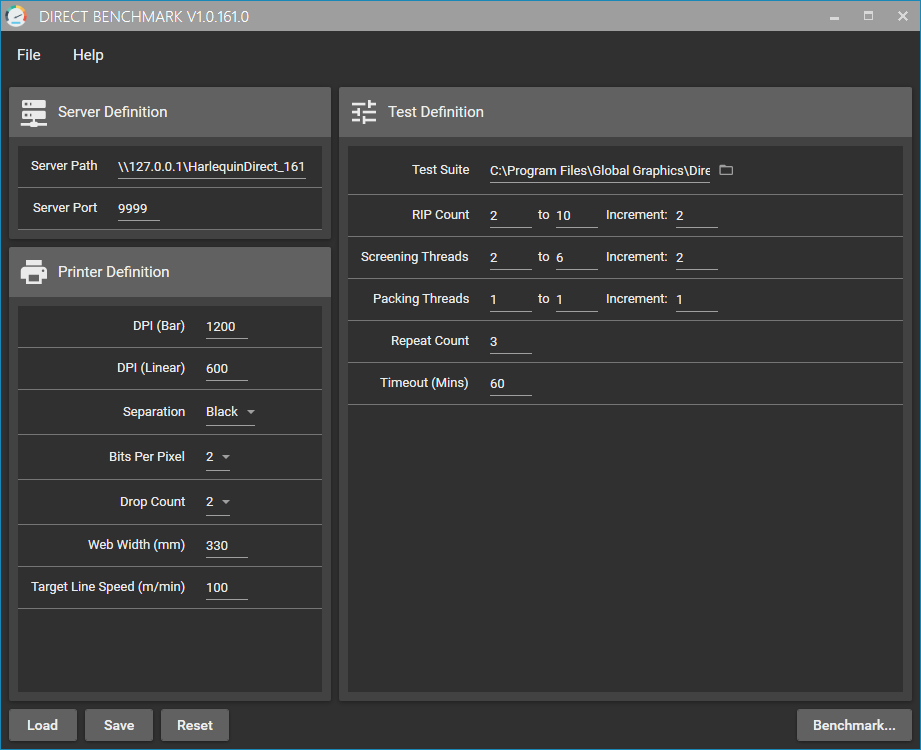

Whilst a real Harlequin Direct system would be connected to printhead electronics and driving your press directly, the Harlequin Direct invoked by Direct Benchmark doesn’t require this connection. This makes it very quick and easy to install and start gathering performance numbers. The screenshot below shows the settings you can use to reflect your printer configuration and define the print jobs to benchmark.

During benchmarking, you will be presented with a screen showing statistics for each run and a real-time graph of data rate at the bottom, and then you will be able to export the results at the end. If you would like to see Direct Benchmark in action, you can view a short demo here:

Using the Direct Benchmark database

If you aren’t in a position to run Direct Benchmark yourself, we are in the process of gathering results for a range of press configurations and print jobs, running on a variety of PC hardware specifications. This is being conducted in conjunction with Proactive Technologies, who are providing access to some of the machines we’re using. Whilst it is too early to draw any conclusions or share our results at this stage, if you have some typical print jobs and a press configuration in mind, please get in touch with me, ian.bolton@globalgraphics.com, because we may be able to generate the results for you.

For more information about Direct, please visit globalgraphics.com/direct

To be the first to receive our blog posts, news updates and product news why not subscribe to our monthly newsletter? Subscribe here

Follow us on LinkedIn and Twitter

About the author:

Ian has over 15 years’ experience in industry as a software engineer focusing on high performance. With a passion for problem-solving, Ian’s role as product manager for the Direct range gives him the opportunity to work with printer OEMs and break down any new technology barriers that may be preventing them from reaching their digital printer’s full potential.