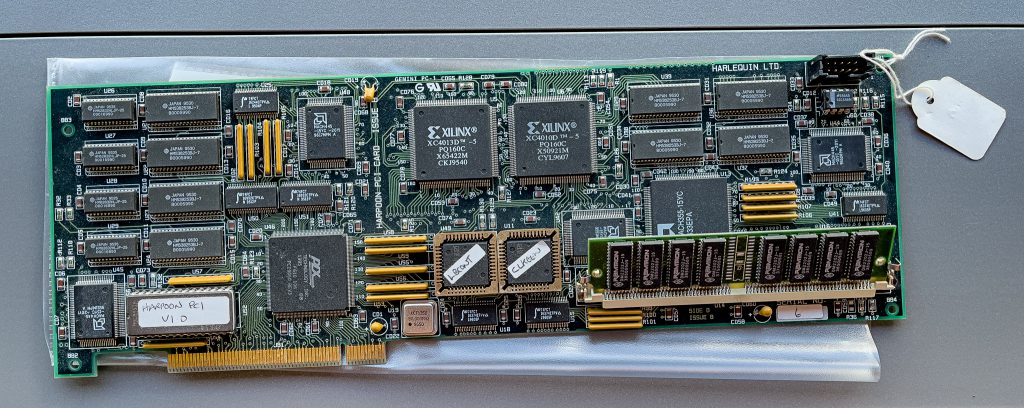

I finally made time for a very overdue tidy of my filing cabinet yesterday. In between wondering why I still had receipts from travel in 2003, I tripped over a piece of history: it’s a Harlequin Harpoon board, a hardware accelerator for halftone screening and part of the technology that allowed Harlequin to become the first to RIP the Seybold Musicians’ speed test page in under 60 seconds.

Speed is still a key focus for Global Graphics Software, but the Harpoon was designed for screening for offset plates, and developments in chips and compilers by Intel, AMD, Microsoft and others, together with further optimizations to Global Graphics Software code, removed the need for custom hardware for that use case fairly soon afterwards.

Today’s challenge is much more for digital presses, and especially for inkjet. Current press speeds make the idea of celebrating RIPping and screening a single page in less than a minute seem quaint and even slightly bizarre; very last millennium! The fastest digital presses now print well over the equivalent of 10,000 pages per minute, often with every page different, which means that at least something on every page must be RIPped and screened, at full engine speed.

For that kind of performance, or even a more common 100 m/min for a narrow-web label press, it’s now normal to use multiple RIPs in parallel and to share the pages out between them. This makes it tricky to use custom hardware unless that is tied to specific ink channel delivery, because otherwise it must be load-balanced in a way that complements the load-balancing across the RIPs. We still see some custom hardware associated with raster delivery to the heads in the press, but nowhere else in current systems.

For the same reason, increasing the raw speed of a single RIP is no longer a target; scheduling pages to each RIP in a cluster and managing the rasters delivered by each one, together with managing the interactions between those multiple RIPs, are far more important. System engineering is now a key part of being able to drive inkjet presses at full speed without an unfeasibly high bill of materials for the Digital Front End, almost as much as the core technologies themselves.

In other words Global Graphics’ Direct™ and SmartDFE™ technologies are the logical successors of the Harpoon board, bringing affordable and reliable speed to a new generation of printing technology. But there’s still something rather nice in being able to hold a physical piece of history in my hands!

About the author

Martin Bailey, Distinguished Technologist, Global Graphics Software, is currently the primary UK expert to the ISO committees maintaining and developing PDF and PDF/VT and is the author of Full Speed Ahead: how to make variable data PDF files that won’t slow your digital press, a new guide offering advice to anyone with a stake in variable data printing including graphic designers, print buyers, composition developers and users.

Be the first to receive our blog posts, news updates and product news. Why not subscribe to our monthly newsletter? Subscribe here