As digital presses become wider and higher resolution, supporting additional inks beyond CMYK, the total number of nozzles required per press increases, which in turn raises the likelihood of at least one of those nozzles failing to jet or becoming deviated (and needing to be disabled). Each nozzle that is out will result in a lack of ink where it should have been in a straight line along the direction of print.

One obvious response would be to fix the problematic nozzles, when they have been detected, but this kind of physical intervention interrupts production and can be impractical. Replacing the affected printhead altogether is another possibility, but again this will have an unwelcome financial impact.

Our sister company, Meteor Inkjet, offers NozzleFix™, an embedded software/hardware solution to compensate for missing nozzles. But for digital printing equipment which does not incorporate Meteor printhead electronics, software compensation may also be beneficial. In this post, we will look at a software-based approach where good working nozzles can compensate for any misbehaving neighbors as required.

Nozzle-Out compensation in software

As the word “compensation” suggests, this solution works by telling certain nozzles to jet more ink than they otherwise would have to make up for a deficit caused by nozzles that were not jetting or had to be turned off because they had deviated.

For one-drop screening, this could mean that whenever a drop should have been output by a nozzle that’s out, a nozzle on either side could be asked to jet that drop instead. An alternative to this, which can accommodate any drop size, is to apply compensation before screening, working with intensities rather than drops.

Here’s how it works: when a nozzle is off, the intensity for each pixel associated with that nozzle is used to boost the intensity of neighboring pixels, which are then screened as normal.

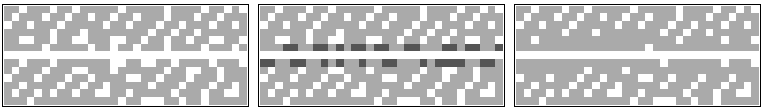

This is best understood by way of an example. Consider an 8-bit continuous tone input TIFF™ which has the value 160 for every pixel. If we are using one neighbor on either side of a pixel to compensate, we will add 80 to their intensity before screening. If we are using two neighbors on each side, we would add 40.

The greatly zoomed-in images above illustrate the results after 3-drop screening for this example: the left image has one nozzle out and no compensation; the middle image shows compensation with one neighbor either side; the right image shows the use of two neighbors on each side.

Of course, the impact is best judged from the actual prints, where the combination of high resolution and ink results in an impressive optical illusion!

The scans above were printed at 1200dpi. The image on the left simulates a number of missing nozzles, which can be seen by the presence of thin horizontal white lines (you may need to enlarge it for the full effect). The image on the right shows the impact of applying compensation to each nozzle neighboring a missing nozzle.

Rapid response and adjustment

A key benefit of this software-based approach is that a rapid response and adjustment can happen as soon as a problematic nozzle is detected. There is no need to wait for engineer and parts availability. Additionally, there is no trade-off to make between taking costly action each time a problematic nozzle presents itself or having a tolerance or threshold where nothing is done until a certain number of quality issues have accumulated.

Learn more about the technologies available to improve the quality of your inkjet output by visiting our website.

About the author

Ian has over 15 years’ experience in industry as a software engineer focusing on high performance. With a passion for problem-solving, Ian’s role as product manager for the Direct range gives him the opportunity to work with printer OEMs and break down any new technology barriers that may be preventing them from reaching their digital printer’s full potential.

Further reading:

- What causes banding in inkjet? (And the smart software solution to fix it.)

- Streaks and Banding: Measuring macro uniformity in the context of optimization processes for inkjet printing

To be the first to receive our blog posts, news updates and product news why not subscribe to our monthly newsletter? Subscribe here

Follow us on LinkedIn, Twitter, and YouTube