Thank you to David Zwang of WhatTheyThink! for this article about Hybrid Software, highlighting our uniqueness, technologies and vision for the future. Published Tuesday, October 21, 2025 on WhatTheyThink!

Many companies have been creating solutions to enhance the printing and packaging production plant. Hybrid Software is unique in being the only full-stack provider of all the core technologies required for industrial inkjet printing from printhead electronics to high-performance digital front ends (DFEs) and workflow automation systems. They do this through an interesting collection of very targeted solution acquisitions and continuous development, which can be confusing to understand to some, but knowing the principals I know there is a plan.

Background

Hybrid Software, as they are known today, is an interesting collection of very targeted acquisitions and continuous development, which can be confusing to understand to some, but knowing the principals, I know there is a plan. I have been following Hybrid Software from their very beginning when Global Graphics, which is the seed of what is Hybrid Software today, presented their Harlequin RIP (raster image processor) in 1986 to process PostScript and subsequently render PDF. At that time, there were only a handful of core RIP developers, with the two main competitors being Global Graphics and Adobe. These core RIP technologies drove the digital revolution of print and still do. This became the beginning of a long road and targeted vision to the Hybrid Software of today.

Many companies have been creating solutions to enhance the printing and packaging production plant, however as we look at the disparate nature of industrial print, including internal and external processes, and the need for communicating business and production data. Hybrid Software is unique in being the only fullstack provider of all the core technologies required for industrial inkjet printing from printhead electronics to high-performance digital front ends (DFEs) and workflow automation systems. Its tools and solutions are used by press OEMs, as well as printers and packaging converters globally to optimize print production quality, speed, and automation.

At first look, it seems Hybrid is composed of a disparate acquisition of companies and technologies, including Global Graphics, Hybrid Software, Meteor Inkjet, ColorLogic, iC3D, Xitron, and recently Conics. Individually and collectively, they are a powerful resource to those in commercial and industrial print and packaging. Uniquely, Hybrid is not an OEM equipment manufacturer. However, they do supply many of the major OEMs technology for their individual solutions. This growing list includes Agfa, Bobst, Canon, Dantex, Durst, Ellerhold, Fujifilm, HP, Jetron, Kodak, Mark Andy, Mimaki, Mutoh, Pageflex, Racami, Roland, SCREEN, Ultimate Tech, and many others. This is in addition to thousands of printers and converters around the globe that use their various software solutions.

Not just about acquisitions

Global Graphics and subsequently Hybrid Software has been at the forefront of continued RIP development. The evolution from PostScript to PDF was an important one for print and packaging. From its “Camelot” conception in 1990 to the introduction at the Seybold conference in 1991, PDF slowly replaced PostScript as the de facto content packaging file format. The Harlequin RIP was the first fully native PDF renderer, and they have kept up with the evolution of PDF.

PDF 2.0 is the first new version of PDF since 2008 and was designed to address many of the new requirements dictated by the wider adoption of PDF digital file distribution as well as specific use requirements like those of packaging production. While not all of the new features in PDF 2.0 impact print production, some of them do and are supported by the Adobe PDF Print Engine(APPE) and the Harlequin Host Renderer, the primary core processing engines in modern DFE’s.

Service Provider Solutions

Hybrid Software offers solutions to both the OEMs and service providers, and here are a few great examples of how Hybrid Software leverages their acquisitions together to create new solutions for service providers. PDF is an object-based file format. With the right tools, each object in a PDF file can be edited independently without the need for the original native document creation software. Additionally, PDF 2.0 supports the ability to assign metadata to PDF objects. This means that with proper software tools you can also assign variable data to a PDF object as well. There are a few PDF editing software packages in the market today. However, Hybrid Software PACKZ VDP was the first to support the addition of variable metadata to PDF objects and was designed specifically for packaging. Recently, they introduced PACKZ 11 and PACKZ Max, which integrates Harlequin RIP directly into the PACKZ PDF editor, enabling visualizing and/or using precise flexo screening and seamless 1-bit TIFF output.

With the launch of PACKZ 11, Hybrid Software also introduced support for new extensions to the CF2 format co-developed with other industry leaders to meet the unique demands of folding carton and corrugated printing. The extended CF2 format can be seamlessly interpreted by another technology of Hybrid Software’s iC3D ray-tracing software, as well as by structural design management systems and digital cutting and folding machines. This is a perfect example of how Hybrid Software’s different core technologies and applications can be used to build or improve a new product.

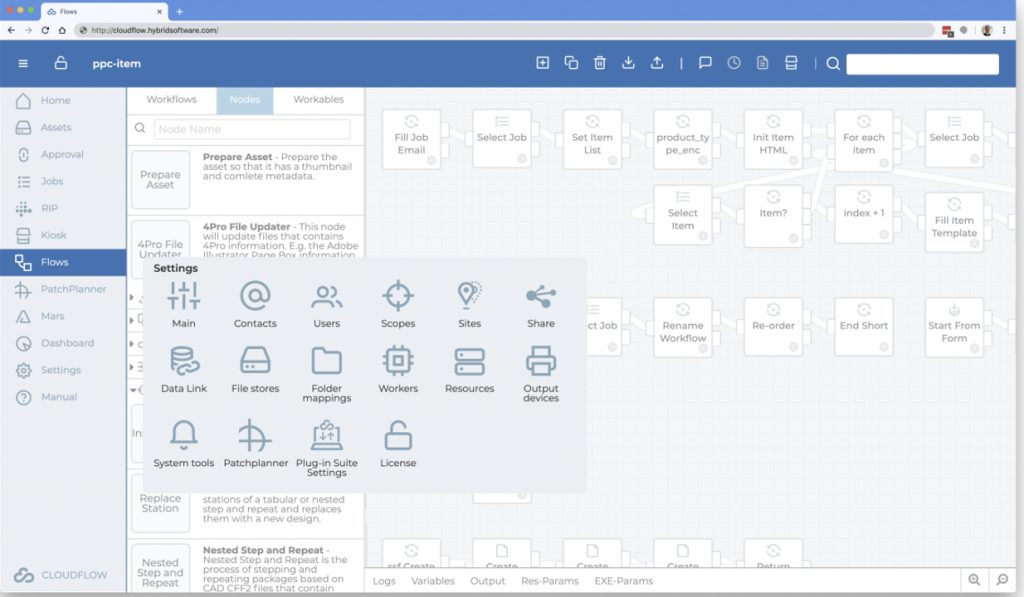

Another example of leveraging their technologies is CLOUDFLOW. Today there are many more rules based workflow solutions in the market that even extend beyond print production processes. CLOUDFLOW is Hybrid’s rule based browser workflow platform. It supports the open JSON REST API for scripting and a NoSQL database backend making it easier to integrate with other cloud-based (web) solutions and services. Many modules have been developed, released, and integrated by Hybrid in the last few years, some of which are resultant of acquisitions like ColorLogic.

MyCLOUDFLOW is a cloud-based application. This incorporates all the modules from the CLOUDFLOW application and supplies the tools and benefits of an internal workflow solution without the hassle of initial setup and IT operation.

Hybrid has recently introduced some AI-based products with real potential to transform how packaging and labels are printed, in conjunction with the acquisition of Conics, a software development and consultancy firm for the printing and packaging industry.

One of these products is Matches, an AI-driven application to search all jobs produced by a printer or trade shop to find jobs with similar attributes or elements, including text, barcodes, and even image content. Many packages are similar but differ in key areas such as sizes, flavors, or languages so identifying similar jobs produced in the past helps assure fast and error-free production of new jobs. Matches is based on AI technology developed by Hybrid Software’s customer and partner Saueressig and is available to users of Hybrid’s CLOUDFLOW software on a subscription basis.

The acquisition of Conics also brought a higher level of AI expertise through their jAImes product. jAImes uses a trained AI agent to extract order data from natural language emails and prompts customers to supply missing information to complete their orders accurately and on time. It also interfaces with packaging MIS systems such as CERM to create production orders automatically for an even higher degree of automation, especially for reorders which make up a large percentage of production for many packaging printers and converters.

OEM Solutions

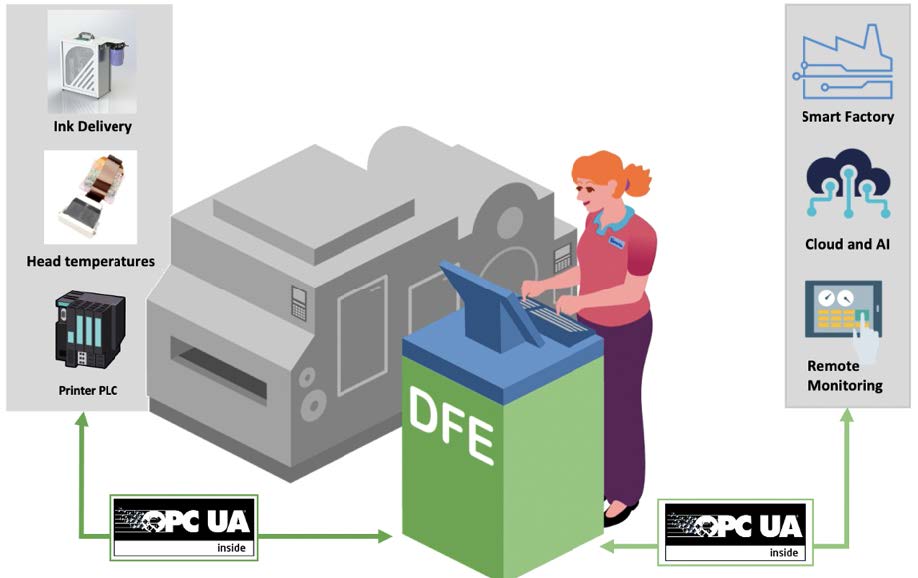

While Hybrid Software has a strong footprint with packaging converters, Global Graphics has historically been a provider of solutions to OEMs. In addition to their Harlequin Renderer and the MAKO SDK, one of those solutions is their SmartDFE which is specifically designed to be integrated into a supply chain with connected modularity utilizing a OPC UA compliant interface. This interface becomes the connection point to the SmartDFE supporting a Smart Factory that takes advantage of the extensive network of interconnected systems. The Smart Factory has interoperable systems, and could even provide multi-scale dynamic modelling and simulations, intelligent automation, strong cyber security, and networked sensors.

The initial acquisition of Meteor Inkjet in 2017, led to additional opportunities for the leveraging of “in-house” technologies. Meteor specializes in electronics, FPGA (Field Programmable Gate Array) development, firmware, and print system architecture, supporting both prototype development and full-scale production for digital printing OEMs. In essence, they provide printhead electronics and software to inkjet printer manufacturers. One of the outcomes of leveraging that technology relationship is Harlequin Direct.

Harlequin Direct provides actionable intelligence to identify the right PC hardware for RIPing jobs and driving the head driver electronics directly at their printers’ full rated speed to ensure you are not over or under specifying a system. Using centrally stored benchmarks you can start to predict what PC specifications will be required for a specific job and line speed. In a similar manner, you can analyze the models for the Smart Print Controller (SPC) to predict the line speed achievable with any specific job. Using this information, a print operator can choose to slow a printer down, streamline a the job before submitting, or reject the job. analyzing job performance histories along with maintenance costs, human costs, and consumables, using the Smart Job Cost Estimator (JCE), you can take a PDF and generate a cost based on the information.

Digital printing requires managing large amounts of data, if you add variable data into that mix, it requires even more significant and costly hardware to keep up with the presses, which is why Global Graphics developed Harlequin Direct.

Harlequin Direct provides the ability to process 1200 x 600 dpi page images to a press running at one thousand feet per minute with a 20-inch-wide print bar at press speed with desktop class Intel i9 CPUs. While that is only one color, and for four colors you would require four CPUs, these are inexpensive desktop class CPUs not expensive Xeon server class.

Those data challenges are also an issue for content inspection— getting the data to the printhead only addresses part of the problem. How do you process synchronize, inspect and compare all of that content on the fly at press speeds? While all VIS (visual inspection solution) companies use cameras to capture the streaming content, they may need to process many different reference file formats to compare those results against.

Furthermore, it requires the processing of an image of the printed page at a relatively low resolution so that what the camera sees can be compared to what a human would see. For example, the colors that emerge from the combination of tiny dots of color that are actually put down on the page to produce color. That is what the VIS is ideally looking to compare and analyze, all at machine rated speeds.

Global Graphics uses their Mako SDK to help address content inspection requirements where the applications are static data or offline variable data. Global Graphics Smart QI can convert and rasterize a wide range of PDLs (page description languages), including: PDF, PS, XPS, PCL5, and PCL/XL at extremely high speeds to RGB and ensure that the rendering of those document objects are accurately captured. Mako can further analyze all of that content including pages, images, vector content, text, metadata, annotations, bookmarks and links for processing and comparison against the video stream.

Unique Position

Hybrid Software really has become a valuable assortment of companies and technologies that place them in a unique position to market specialized solutions to OEMs and service providers across a wide range of applications. CEO Mike Rottenborn emphasizes that Group’s unified strategy “to deliver a complete, intelligent print production ecosystem spanning prepress design to press control.”

About the author

David Zwang travels around the globe helping companies increase their productivity, margins and market reach. He specializes in production optimization, strategic business planning, market analysis, and related services to companies in the vertical media communications market. Clients have included printers, manufacturers, retailers, publishers, premedia and US Government agencies. He can be reached at david@zwang.com